CAPABILITIES

CUSTOM HIGH VOLUME COMPONENTS & SUB-ASSEMBLIES

Smart AUTOMATED ASSEMBLY

IMA delivers high-volume sub-assemblies for solar, automotive, and other industries. Our advanced robotic production lines integrate quality control and data recording for reliable, high-tech manufacturing.

STAMPING

We offer comprehensive stamping and forming solutions, including progressive, transfer, and line die capabilities. Our facilities utilize robotic welding, drawing, and cutting processes to produce accurate components tailored to your specifications.

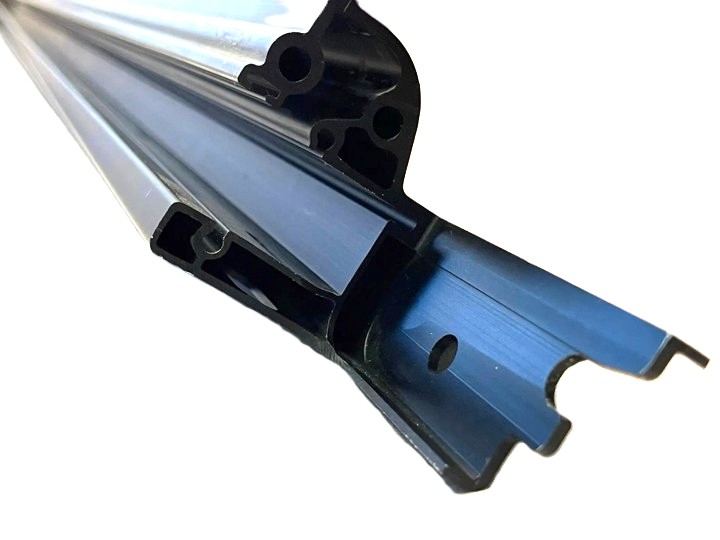

TIGHT TOLERANCE EXTRUSIONS

Leveraging our sister plants in the USA and Asia, IMA supplies precise complex profiles in performance, BABA, or zero-emission aluminum. We perform in-house tooling maintenance for our thin-walled, tight tolerance profiles in a range of alloys (6063, 6005, 6061, 6060, 6082). Managed with mill-to-customer material traceability.

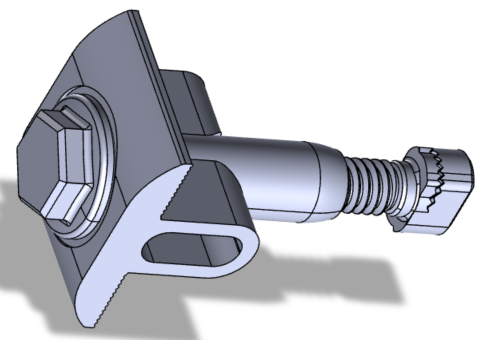

Precision FABRICATION

Our fabrication centers provide end-to-end services. Capabilities include CNC milling, precision punching, hydraulic stretch bending, cutting, and welding. No fabrication process is off-the-table at IMA. We will always consider the right investment for the right project.

SURFACE TREATMENT SOLUTIONS

IMA manages all aspects of surface treatments. We understand visual aspect and class A surfaces, and ensure your components meet both your visual and functional standards.

- BRUSHED CLASS A

- ANODIZING

- E-COAT / KTL

- PAINT / POWDER COATING

PRECISION MANUFACTURING

DELIVERED ON TIME

- EXTRUSION

- MACHINING

- FABRICATION

- ASSEMBLY

- STAMPING

- FINISHING

FIND YOUR SOLUTION AT IMA

We can make your job headache free by responding to your RFQ, meeting your pricing targets, and your timing requirements.